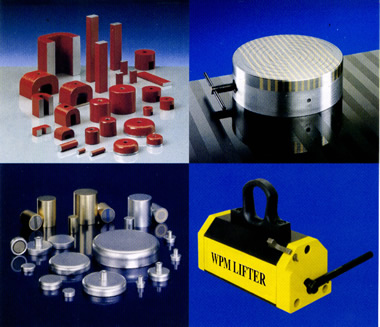

Alnico Holding Assemblies

Our teams in Yuxiang magnetic materials Ind.co., Ltd. always tries our best to provide different Holding Magnets, such as Square, Disc and Ring Holding Magnets, Hard Ferrite (Ceramic), Alnico, NdFeB and SmCo assemblies are specified for many applications to all industries and enigneering.

All commercially available permanent magnet materials can be utilized, including ceramic, Alnico, NdFeB and SmCo magnet in mild steel housing. Capabilities include shaping magnets via slicing and dicing, centerless and surface grinding, and edge deburring. Assembly operations include gluing, potting with epoxy, plating(Nickel-plating, Zinc-plating), paint coating and magnetic testing. Optional rubber can be filled to produce an even surface. Magnetic assemblies are up to 32 times stronger than magnets by themselves.

Application:

Magnetic Assembly are widely used in such devices as motors, sensors, solenoid actuators, holding and clamping fixtures. Including automobiles, electronic instrumentation, oil field exploration and ultrasonic transducers.

|

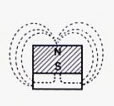

Permanent

magnet Factor 1 |

|

Alnico

bar in steel pot (adhesive magnet-prip bars, pot magnet) Factor 7.5 |

|

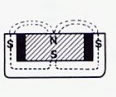

With

steel backing plate Factor 1 |

|

Magnetic

block in steel (U-profile) Factor 5.5 |

|

With steel backing plate and center pole Factor 4.5 |

|

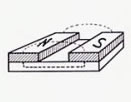

Magnetic block between two steel plates (sandwich-system) Factor 18 |

|

Disc magnet in steel pot (adhesive magnet disc) Factor 6 |

|

Adhesive battery of several sandwich-systems (types 50...L200) Factor 18x system number |

|

Ring

magnet in steel pot and center pole Factor 7 |

|

Two

magnetic blocks, mounted counterpoles on steel backing plate Far reaching stray field as needed for catching steel |

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved